R&D in Graphic Communications

My junior year I completed Research and Development in Graphic Communications. For my research project, I decided to experiment with screen printing. I already knew a lot about screen printing and it is something I am passionate about and enjoy doing. I decided to test how well glitter would go through the mesh of a screen.

In the graphics industry, it is difficult to determine which mesh thread count should be used when screen printing with glitter ink. This is because glitter flakes need to pass through the mesh to adhere to the substrate. The objective of my study is to determine which count is best for letting glitter ink pass through. My study attempted to answer the questions: Can glitter ink be custom made and used to screen print designs? How does mesh thread count impact the ability to print glitter ink? What is the optimal thread count for glitter ink? For my project I decided to custom create an ink to print with. I used Triangle Inks' Plastisol Phosphorsecent ink (left) as the ink base and added Tree House Studio's Silver Extra Fine Gitter (center) to make my own custom ink (right) to complete my research project.

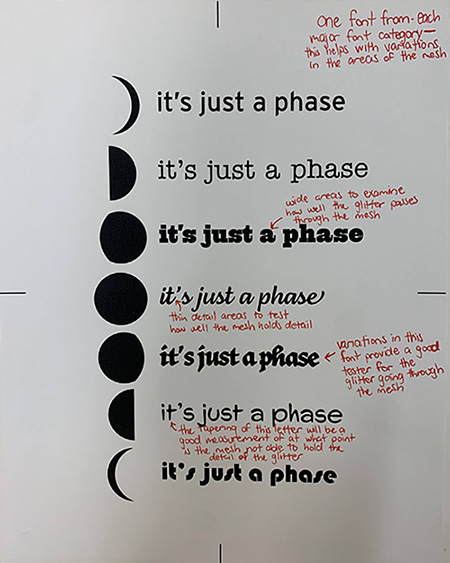

For printing, I created a design where I would have lots of different variables and things to test with both the glitter and the ink. My desigh had both small areas where details will be held and tested with the opening of the mesh count and large areas where the amount of glitter ink adhered to the substrate can easily be evaluated.

A screen was stretched with 60 count mesh thread and a squeegee was used to force the glitter ink through the mesh to print the design. A various number of passes were completed with the squeegee to print the design and achieve a consistent look with the distribution of both the ink and the glitter. For some tests, only one pass was needed to achieve such results. Other tests needed up to four passes to achieve even distribution. In the text areas, glitter did not seem to pass through the mesh at all. The moons were the most helpful when determining if the glitter and ink were evenly distributed. The same mesh thread count was used to print the design ten times to ensure accurate results between each sample.

Mesh thread count influences if the glitter can get through the mesh and adhere to the substrate. So, a lower thread count allows glitter to pass through the mesh and adhere to the substrate. Based on the results of this study, the optimal thread count for glitter ink is lower than 60. In some areas of the design, the glitter was not able to pass through the mesh. For most of the text in the design, glitter did not pass through the mesh at all. If 60 count mesh thread is all that is available, it is best to have large areas in your design where glitter can pass through.

In conclusion, glitter ink can be custom made and used to screen print designs as long as the design has large areas for the glitter to get through. For further studies, it would be recommended that mesh thread counts of 60 or lower be used. Since the glitter was selective in the areas where it passed through the mesh of the 60-count thread, it would be recommended to use a lower thread count and see if the glitter passes through easily.